Overview of features¶

This section goes over the features that can be found in Armored Turtle Automated Filament Control (AFC) Software.

TurtleNeck Buffer Ram Sensor¶

AFC allows the use of using the TurtleNeck Buffers as a ram sensor for detecting when filament is loaded to the toolhead extruder. This can be used inplace of a toolhead filament sensor. To learn more about this feature please see Buffer Ram Sensor document.

TurtleNeck Buffer can also detect clogs, jams and feeding issues before they result in a failed print. See buffer fault detection section in buffer overview for more information.

Bypass¶

By default, if a hardware sensor is not setup for a bypass AFC will create a virtual bypass filament sensor. Enabling the virtual filament sensor disables AFC functionality and enabled state persists across reboots.

You can also enable AFC bypass with a hardware sensor by printing out a bypass accessory, connecting inline it after your buffer and adding a bypass filament sensor to klipper config like below. Once filament is inserted into the bypass side, the switch disables AFC functionality so you can print like normal.

[filament_switch_sensor bypass]

switch_pin: <replace with MCU pin that switch is connected to>

pause_on_runout: False

When either bypass is enabled/filament detect all AFC functionality with loading to the toolhead is disabled. Calling

the TOOL_UNLOAD macro will call the UNLOAD_FILAMENT macro if it exists so that filament can still be manually unload

from the toolhead.

Lower stepper current when printing¶

For longer prints you may want to have the ability to lower BoxTurtles steppers current as they can get hot when engaged for a long period of time.

Enabling lower current during printing can be enabled two ways:

- Set

global_print_currentin AFC.cfg file - Set

print_currentfor each AFC_stepper, this will overrideglobal_print_currentin AFC.cfg

During testing, it was found that 0.6A worked well during printing and kept the steppers warms to the touch. We would not suggest going lower than this or the TurtleNeck buffers may not work as intended when using BOM spec steppers.

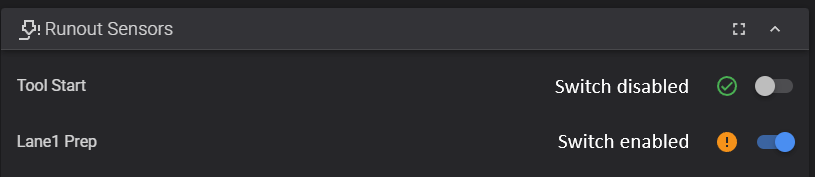

Enabling switches to show up in Mainsail/Fluidd GUIs¶

AFC has the ability to add sensors as filament switches so they show up in Mainsail/Fluidd web gui. This can either be

enabled globally by adding/uncommenting enable_sensors_in_gui: True in AFC.cfg file or enabled/disabled in individual

sections in your config file. Enabling this globally is useful for debugging purposes, but setting in individual

sections will override the global setting.

AFC_buffer, AFC_extruder, AFC_hub, and AFC_stepper sections in your AFC_hardware.cfg or AFC_Turtle(n).cfg have the

ability to enable sensor by adding enable_sensors_in_gui: True. There is an extra config value for AFC_stepper to

allow you to either show both sensors or just prep/load sensors by using sensor_to_show: prep or

sensor_to_show: load, leaving out sensor_to_show will show both sensors.

Tool change count¶

AFC has the ability to keep track of number of tool changes when doing multicolor prints. Number of toolchanges will be pulled from files metadata stored in moonraker. AFC will keep track of tool changes and print out the current tool change number when a T(n) command is called from gcode.

Minimum Moonraker Version Required

Make sure moonraker version is at least v0.9.3-64 to utilize this feature.

If you have set up your Change filament G-code section to use SET_AFC_TOOLCHANGES in your slicer please remove

the following lines:

Also remove the following if added to your PRINT_END section as number of toolchanges will now automatically reset back

once print is done/canceled.

SET_AFC_TOOLCHANGES TOOLCHANGES=0

Setting extruder temp¶

AFC has the ability to automatically set extruder temperature based off filament material type loaded or spoolman extruder temperature if its set.

If not using spoolman make sure the material is set for your lanes and the temperature values will be pulled from

default_material_temps variable in AFC.cfg file. This list can also be updated/added to, just make sure new entries

have a comma inbetween and follow current format when adding new variable.

If spoolman extruder temperature or material type is not defined AFC default's to min_extrude_temp variable defined in

[extruder] section in printer.cfg

default_material_temps: PLA:210, ABS:235, ASA:235 # Default temperature to set extruder when loading/unloading lanes.

Loading filament to hub¶

For users that have a hub not located in their Box Turtle, AFC has the ability to load filament to their hub once its

inserted. This is turned on by default and this will happen even if your hub is located in your Box Turtle. This can be

disabled by setting load_to_hub: False in your AFC.cfg file. Also individual lanes can be turn on/off by setting

load_to_hub: True/False under [AFC_stepper <lane_name>] section in your config.

Variable purge length on filament change¶

AFC has the ability to purge different lengths with orcas flush volumes when doing filament changes with T(n) macros. To use this feature update your Change Filament G-Code section in your orca slicer to the following:

T[next_extruder] PURGE_LENGTH=[flush_length]

Could also be added to your PRINT_START macro with a specific length, this would be ideal for if your first filament is not currently loaded as the PURGE_LENGTH from Orca for the first change would be zero

T{initial_tool} PURGE_LENGTH=100

Important Note

If your first filament is not currently loaded and needs to change, PURGE_LENGTH will be zero and the poop

macro will then use variable_purge_length from AFC_Macro_Vars.cfg file, so make sure this is set correctly for

your printer

Spoolman¶

AFC has the ability to integrate with Spoolman. This is as simple as ensuring that the following information is

present in your moonraker.conf file:

For example:

Note

When assigning a spoolID from Spoolman, either via a UI like Mainsail or Fluidd, or via a macro like SET_SPOOL_ID,

AFC will perform a check to ensure that the weight of the requested spool is not 0, null, or a negative value. If it is,

AFC will reject the spool assignment and log an error message identifying the error. For advanced use cases, this can

be disabled by setting disable_weight_check: True in your [AFC] section of your configuration file.

Spoolman QR Scanner Support¶

Support for QR scanners is provided through SET_NEXT_SPOOL_ID.

A USB QR code scanner implementation afc-spool-scan is available to install on the klipper host.

Direct Drive¶

AFC has the ability to use direct loading straight to the extruder/toolhead. There should be no hub in-between that

lane and the extruder when this option is used. Using direct will disable the ability to use the automatic

calibration functions.

To enable direct mode, the following line needs to be added to the [AFC_stepper <lane_name>] section in your

configuration:

Espooler Print Assist¶

AFC has the ability to activate espooler forward movement when printing to help aid in spools from walking around and riding up wheels when they get low. This feature is enabled by default once your filament weight gets below 500 grams.

The goal of this is to enable the spooler for a small amount of time so that filament on the spool is loosened up some,

then by the time your printer extrudes delta_movement amount(defaults to 150) the filament on your spool should just be

getting taught before print assist activates again.

This feature can be turned off by adding enable_assist: False to your [AFC_BoxTurtle Turtle_(n)] or [AFC] or per [AFC_Stepper] config sections.

If you would like to change the weight value where print assist is activated, then add enable_assist_weight: <new_number>

to your configuration, this value can be added to the same sections as enable_assist variable.

The following variables described in AFC_lane section are all

the values that go into the print assist logic: enable_assist, enable_assist_weight, timer_delay, delta_movement, spoolrate, spool_ratio,

full_weight, spool_outer_diameter, spool_inner_diameter, espool_rot_dist, max_motor_rpm.

These values can be configured per lane (AFC_Stepper) or per Unit (AFC_BoxTurtle).

With this functionality the following macros allow you to enable/disable and tweak the settings for print assist:

If the default values for print assist is unspooling too much you can start off by changing either max_motor_rpm or

spool_ratio to decrease the time that the N20 motors are active( aka cruise_time ).

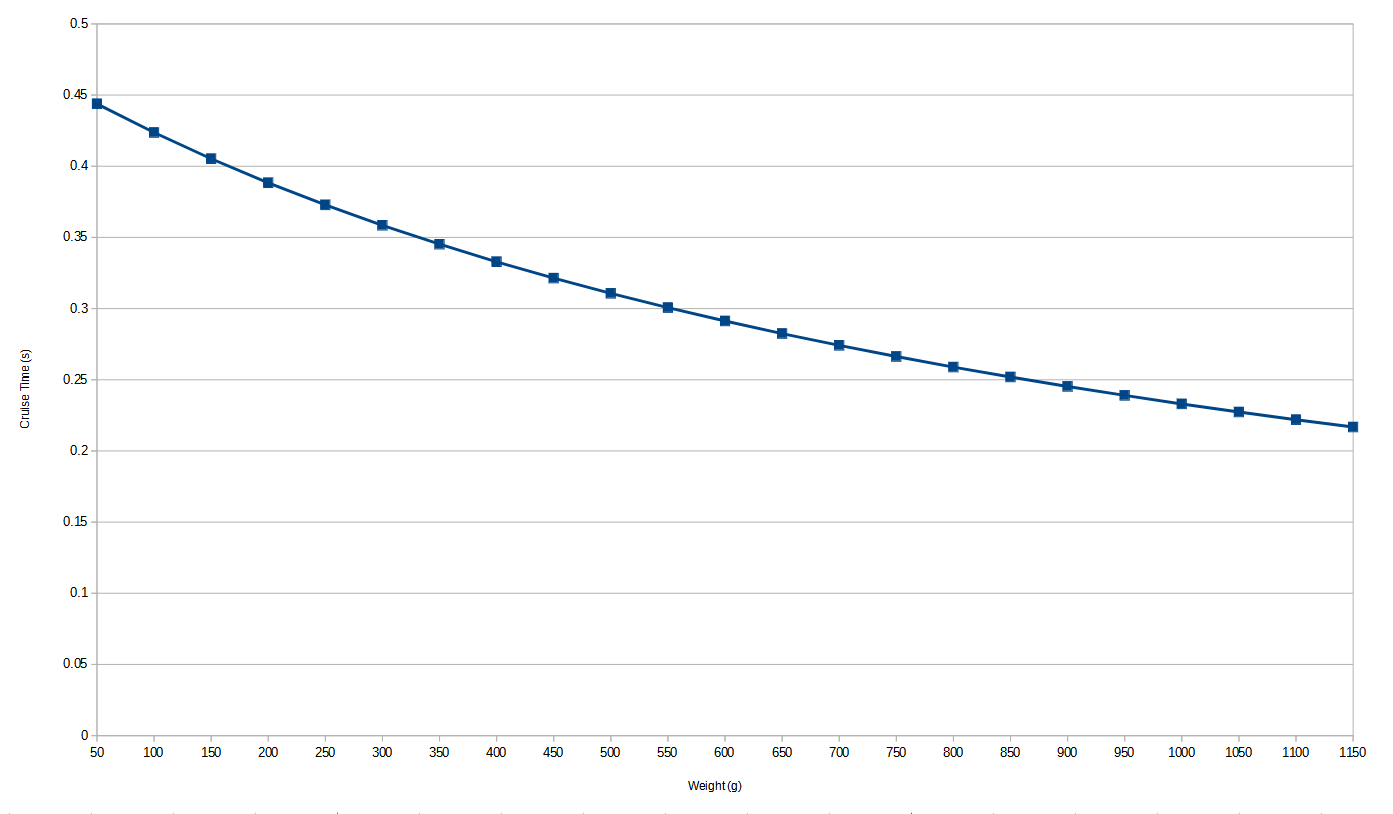

Below is the default cruise time dependent on weight when using default variables:

Formula to calculate cruise_time:

rps = max_motor_rpm / 60

spool_rot_s = (espool_rot_dist * (rps / spool_ratio)) / (spool_outer_diameter * PI)

w_r = ((weight / full_weight) + 1) * ((spool_outer_diameter - spool_inner_diameter) * PI)

cruise_time = delta_movement / w_r / spool_rot_s

Quiet Mode¶

AFC has the ability to run motors at slower speed when doing loads to reduce motor noise. This is helpful for

those that may have a printer in their bedroom and would like to run multicolor prints overnight. To enabled

quiet mode there is a filament switch under your filament sensor called Quiet Mode, once this is enabled AFC will do long moves at

a slower speed(default: 50mm/s). Quiet mode speed does not apply to PTFE calibrations and lane resets.

Speed for quiet mode can be updated by setting quiet_moves_speed variable in either [AFC] section, or

[AFC_stepper <name>] section (adding here override setting in [AFC] section).

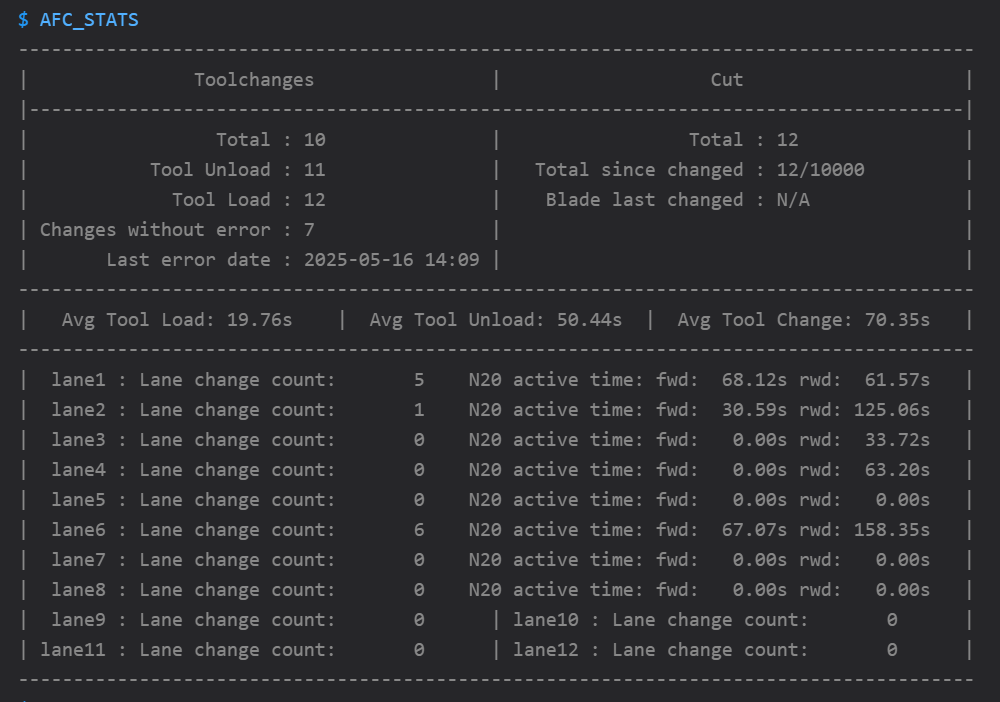

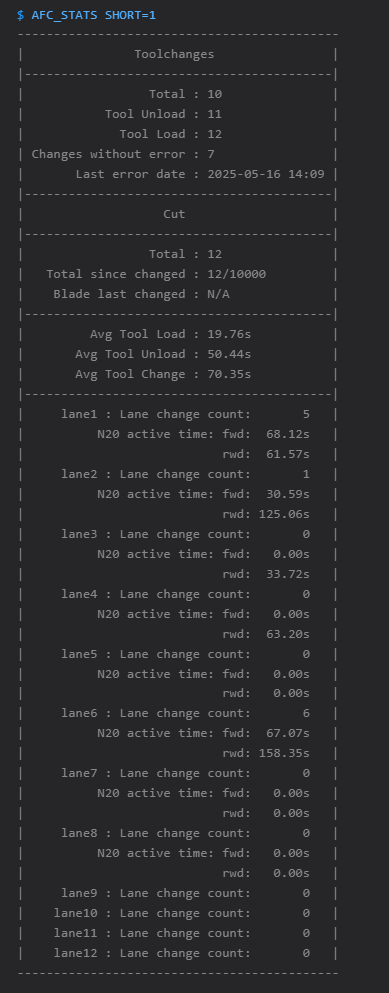

Tracking Toolchange Statistics¶

AFC tracks all toolchanges, lane loading/unloading, number of changes since last load error, total number of cuts performed, number of cuts since blade last changed and how long N20 motors have been active if N20 are configured in your setup.

AFC will also start warning in console when your number of blade cuts is 1k less than the tool cut threshold letting you

know that it's getting close to change blade. Once number of cuts exceed threshold AFC starts printing out error messages

in the console. If blade is changed use AFC_CHANGE_BLADE macro to reset count and date blade was changed.

Use the following macros to print out statistics in console, update when blade has been changes and reset

N20 active time:

- AFC_STATS - prints statistics to console

- AFC_CHANGE_BLADE - run macro when blade is changed, sets date that blade was changes and resets Total since changed count

- AFC_RESET_MOTOR_TIME - run macro when N20 motor has been swapped out in a lane

- AFC_RESET_STATS - run macro to reset extruder and lane counts

Both variables can be added/updated in [AFC] section :

- print_short_stats: Add/uncomment to have the statistics printout to be skinner. Useful for those that have consoles that are skinner( eg. Klipperscreen )

- tool_cut_threshold: Defaults to 10000 cuts, update to if you want threshold to be larger. This controls when AFC prints out warning/errors when number of cuts since changed reaches/exceeds this number.

Note

As of AFC-Klipper-Add-On version 1.0.34 new averaging for load times was introduced. Before AFC would not keep track of the total time when averaging, now AFC has the ability to keep track of total time and average with load counts. For AFC to calculate the new, the AFC_RESET_STATS macro needs to be ran like the following(this will reset your current extruder counts and load times):

AFC_RESET_STATS EXTRUDER=all.

Once this macro is ran, moonrakers database will first be backed up just incase someone would like to restore previous stats before resetting values. This reset needs to happen for AFC to average load times correctly based of load counts.

Examples of what statistics printout looks like:

Button controls¶

Original Design

The original design of this feature was created by @Trev1Ak and is available here.

This feature is now built into the AFC-Klipper-Add-On and can be enabled by following the instructions below.

Do NOT use the provided Klipper config file from the original design, as it is not compatible with the AFC-Klipper-Add-On.

An optional feature that can be supported is the use of physical buttons to control various functionality of the AFC system.

If enabled, and configured properly, the following functionality can be controlled via buttons:

Press <1.2 (short-press) seconds commands as follows:

- If no lane is loaded to tool head it will load commanded lane.

- If lane loaded to tool head is other than commanded lane it will unload other lane and load commanded lane.

- If commanded; lane is loaded to tool head it will automatically unload lane

Press >1.2 (long-press) seconds commands as follows:

- If lane is loaded to tool head it will unload lane and eject spool

- If another lane is loaded to tool head it will only eject commanded lane and not interrupt other lanes.

BOM:

- 4ea Omron B3F-1026 switches/Optional verified off brand switches Amazon https://a.co/d/hmtJkk8

- 4ea JST 3 pin male connectors for AFC Lite board

- 3 Meters of 24awg or 28awg wire (your choice)

Detecting runouts¶

AFC has the ability to detect runouts or filament breakage while printing. If filament is not detected at the toolhead or hub sensors while printing then a pause command is issued with an error message stating what happened so the error can be fixed before resuming the print.

During printing if the PREP sensor goes low, one of two things can happen.

- If infinite spool is not set for the lane that the PREP sensor went low on, AFC will issue a pause command so issue can be fixed before resuming print. Note: If

unload_on_runout: Trueis set in AFC config section, lane will be unloaded from toolhead after pausing. - If infinite spool is set with SET_MAP macro, then AFC will unload filament from runout lane and then load lane as specified when running SET_MAP macro. If tool loading was successful print will continue. If tool load was unsuccessful AFC will issue pause command and an error will be displayed.

A debounce delay can also be added so that the sensor(s) need to be low for a period of time before triggering the runout logic. By default this is set to zero but can be changed by adding debounce_delay: <delay_value> to your AFC config which is a global value. Debounce delay can also be added in AFC_extruder, AFC_hub, AFC_stepper, and AFC_lane configs which override the global AFC setting. See configuration sections for each config for more information.

Runout detection can be turned off while printing by disabling sensor in web gui. If PREP sensor is disabled this also disables infinite spool. The state of the switches is not persistent and will reset to enabled when klipper is restarted.

Example of runout enabled/disabled:

TD-1 Support¶

AFC has the ability to grab data from TD-1 devices that are connected to your printer. More information about this and setting it up can be found under TD-1 section.

Exposing Lane Data for Third-Parties¶

AFC will store lane data in moonrakers database at <ip_address>/server/database/item?namespace=lane_data so that third-parties (like orca once support is added) can read this data and know what color, TD(if enabled), mapping, material filament, etc. is in each lane.

Endpoint returns all lanes in system in a json format like the following:

{

"namespace": "lane_data",

"key": null,

"value": {

"lane1": {

"color": "#122B44",

"td": 4.0,

"material": "ASA",

"bed_temp": 105,

"nozzle_temp":245,

"scan_time": "2025-09-14T03:13:27.189383Z",

"lane": "1",

"spool_id": 12345

},

"lane2": {

"color": "#122B44",

"td": 4.0,

"material": "ASA",

"bed_temp": 105,

"nozzle_temp":245,

"scan_time": "2025-09-14T03:13:27.189383Z",

"lane": "0",

"spool_id": 54321

},

"lane3": {

"color": "",

"material": "",

"bed_temp": "",

"nozzle_temp": "",

"scan_time": "",

"lane": "2",

"spool_id": null

}

}

}

- Color: Current color filament loaded in lane, if filament was scanned with TD-1 then TD-1 scanned color is returned

- TD : Transmission distance if TD-1 is connected and enabled in system

- Material: Material from spoolman or when manually entered with SET_MATERIAL macro

- Bed Temp: Bed temperature pulled from spoolman data

- Nozzle Temp: Nozzle temperature pulled from spoolman data

- Scan Temp: Only is populated if TD-1 is connected and enabled in system and filament was scanned

- Lane: Current tool mapping for lane/slot. eg. T0/T1/T2/etc.

- Spool ID: Spool ID assigned to this lane via SET_SPOOL_ID or SET_NEXT_SPOOL_ID. Value is an integer when a spool is assigned, or

nullwhen the lane is empty/ejected