AFC-Klipper-Add-On Slicer / Print_Start Setup¶

Slicer Setup for AFC-Klipper Add-On¶

Configuring your slicer¶

The recommended slicer for AFC is OrcaSlicer. Other slicers such as PrusaSlicer or SuperSlicer may be used, and the configuration of options within them is similar but naming or options may be slightly different.

Updating printer settings in Orca¶

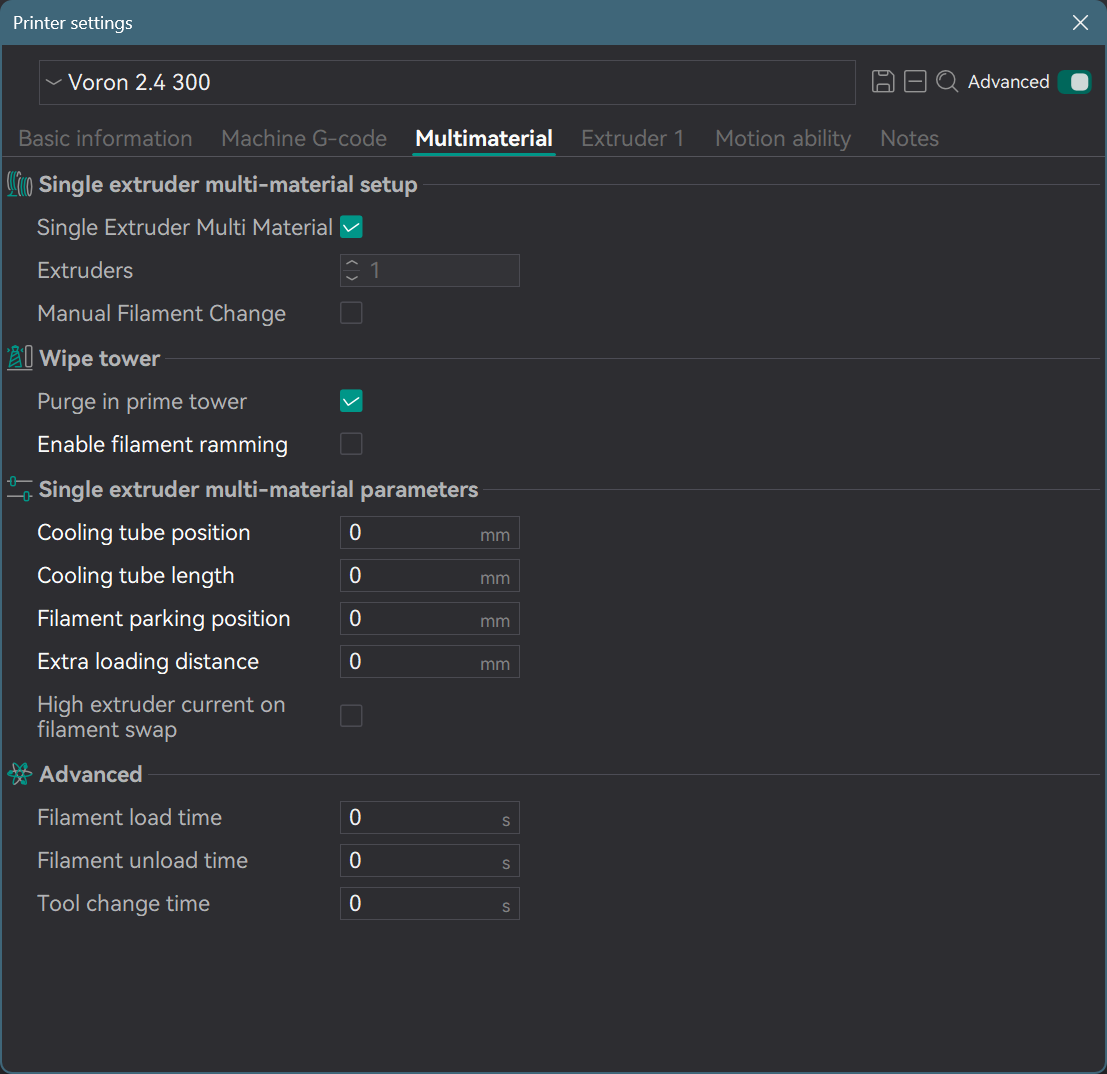

For the printer you are adding BoxTurtle to, first go to the Printer settings, Multimaterial tab and ensure settings are

configured as per the below screenshot.

Note

Only select the Purge in prime tower option when you are not using the POOP macro/functionality.

Also, on the Extruder 1 setting page - reduce Retraction while switching material length from the default of 2 to

0.

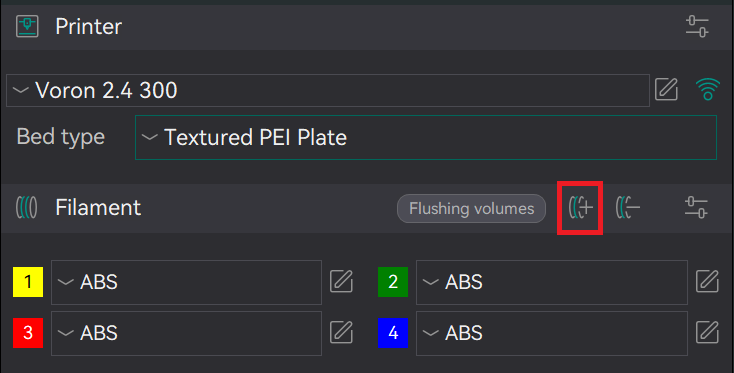

Adding additional filaments/extruders¶

Increase the number of filaments to match your BoxTurtle's lane count.

Updating the Machine G-code settings¶

- Set

Machine start G-codeappropriately for your printer, specifically adding theTOOL={initial_tool}to yourPRINT_STARTmacro.

Note

More information about the PRINT_START macro will be covered in the next section, so keep this in mind!

M104 S0 ; Stops OrcaSlicer from sending temperature waits separately

M140 S0 ; Stops OrcaSlicer from sending temperature waits separately

PRINT_START EXTRUDER=[nozzle_temperature_initial_layer] BED=[bed_temperature_initial_layer_single] TOOL={initial_tool}

- Set

Change Filament G-Codeto the below value. Remove any other custom code here, e.g. extruder moves.

T[next_extruder] PURGE_LENGTH=[flush_length]

; FLUSH_START

; EXTERNAL_PURGE {flush_length}

; FLUSH_END

Changes when using PrusaSlicer¶

For the most part, many of the above settings are also applicable to other Slic3r derivatives such as PrusaSlicer or SuperSlicer. Below are a list of some of the deviations. Reth also created a very good summary of the overview of tuning changes for PrusaSlicer in this video.

- Instead of 'Change Filament G-Code', update the 'Tool Change G-Code' in printer settings to the below.

- Under each extruder in printer settings, change the default value of 'Retraction when tool is disabled' from 10mm to 0.5mm.

Additional Slicer configuration - pre-OrcaSlicer 2.2.0¶

Configuring per-material filament ramming is no longer required as of the official OrcaSlicer 2.2.0 release ( PR #6934). If you are on an earlier version than that (including betas/release candidates) you will need to make the following additional changes to your slicer configurations.

Cura Slicer Setup (User reported settings)¶

;Filament name = {material_brand} {material_name}

;Filament type = {material_type}

;Filament weight = {filament_weight}

;Nozzle diameter = {machine_nozzle_size}

PRINT_START STANDBY={material_standby_temperature} BED={material_bed_temperature_layer_0} EXTRUDER={material_print_temperature_layer_0} TOOL={initial_extruder_nr}

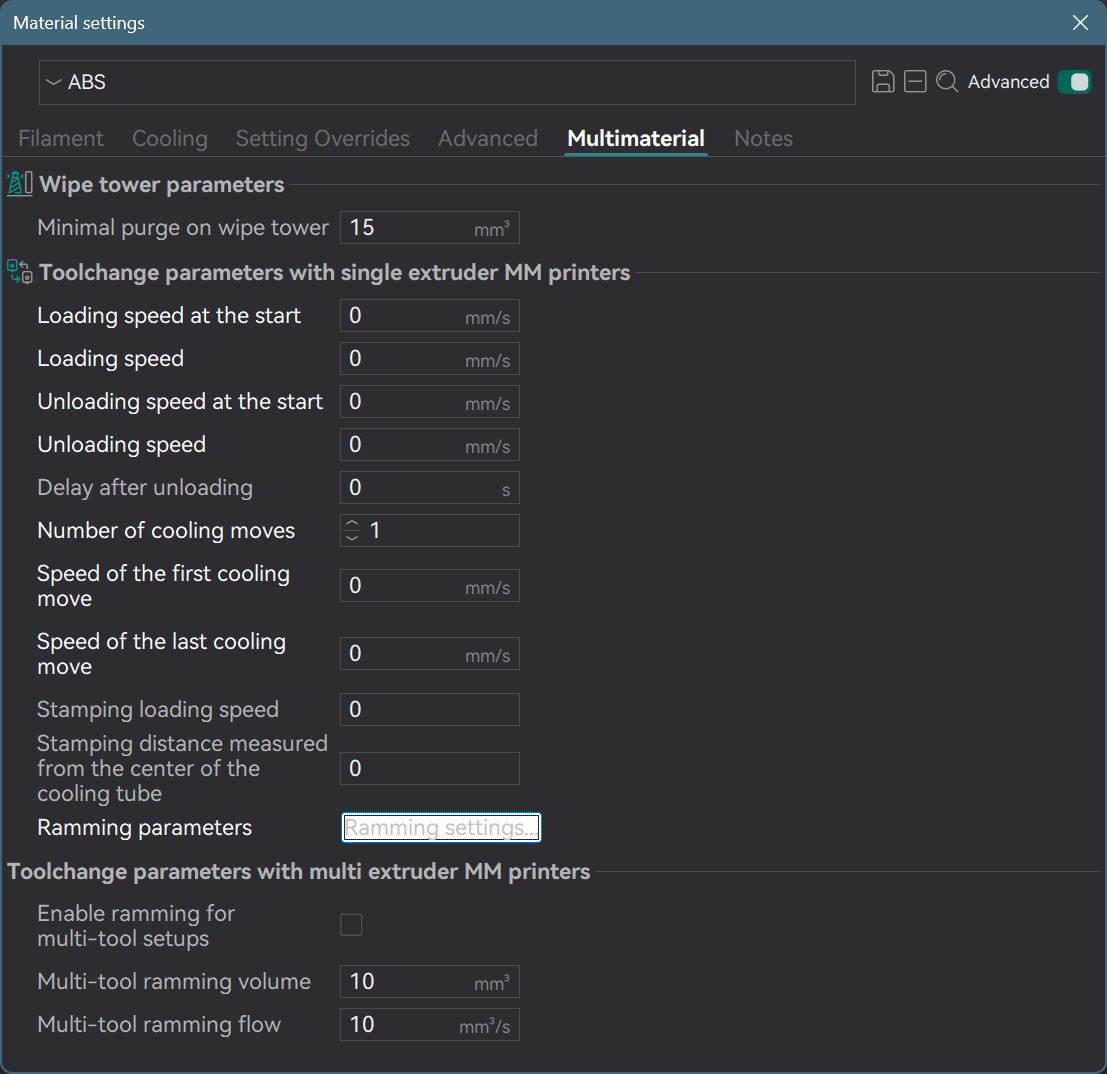

Material Settings¶

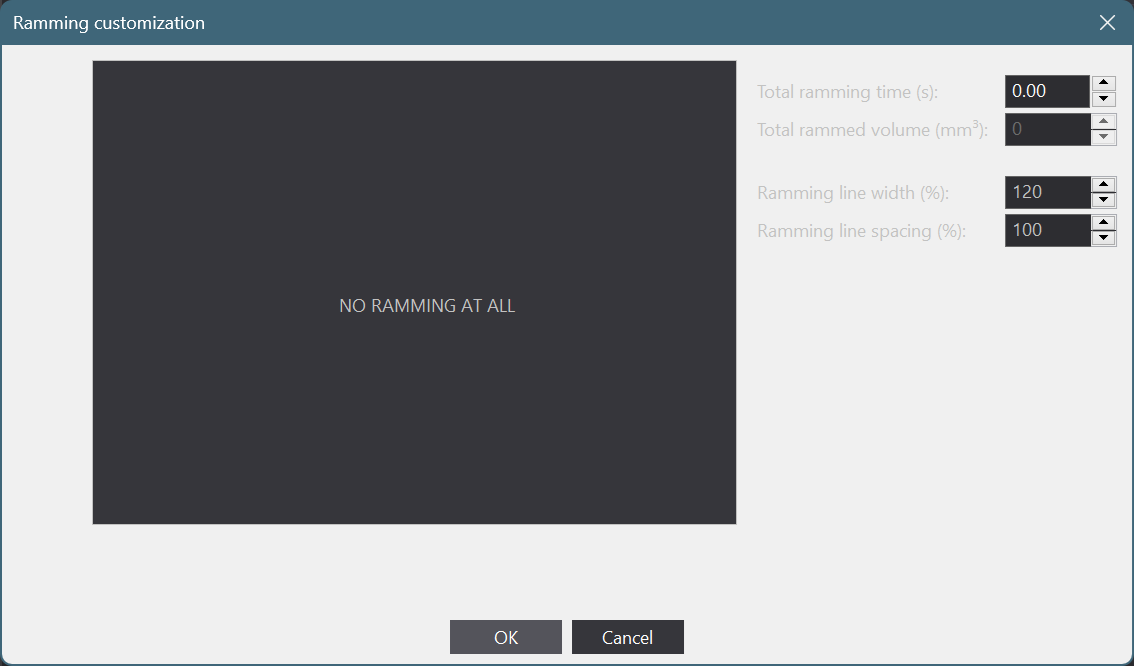

Ramming Settings¶

Because the AFC-Klipper-Add-On handles any tip forming in the extension, we need to disable these specific settings in

the slicer software. Below is a screenshot for OrcaSlicer, but most Slic3r-based slicers have a similar dialog/setting.

Other slicers¶

PrusaSlicer - https://www.youtube.com/watch?v=ilxtHVNhsM4

Print Start Macro for AFC-Klipper Add-On¶

Updating your PRINT_START macro¶

Info

Please note this is just an example macro to show how to incorporate the initial tool into your

print start macro.

Please adjust it to match your printer setup. A good starting point for a PRINT_START macro is jontek2's "A Better PRINT_START macro"

Add the TOOL parameter we added to the Machine start G-Code earlier to your PRINT_START macro.

[gcode_macro PRINT_START]

gcode:

{% set BED_TEMP = params.BED|default(60)|float %}

{% set EXTRUDER_TEMP = params.EXTRUDER|default(195)|float %}

{% set S_EXTRUDER_TEMP = 150|float %}

{% set initial_tool = params.TOOL|default("0")|int %}

G90 ; use absolute coordinates

M83 ; extruder relative mode

G28 # Home Printer

# Do any other leveling such as QGL here

# Z_TILT_ADJUST

# QUAD_GANTRY_LEVEL

# G28 Z

AFC_PARK

M140 S{BED_TEMP} # Set bed temp

M109 S{EXTRUDER_TEMP} # wait for extruder temp

T{initial_tool} #Load Initial Tool

M104 S{S_EXTRUDER_TEMP} # set standby extruder temp

M190 S{BED_TEMP} # wait for bed temp

G28 Z

# Bedmesh or load bedmesh

AFC_PARK

M109 S{EXTRUDER_TEMP} ; wait for extruder temp

# Add any pre print prime/purge line here

# Start Print

If you are modifying an existing macro:

- Add the following to the top of the PRINT_START macro just under the

gcode:line

{% set BED_TEMP = params.BED|default(60)|float %}

{% set EXTRUDER_TEMP = params.EXTRUDER|default(195)|float %}

{% set S_EXTRUDER_TEMP = 150|float %}

{% set initial_tool = params.TOOL|default("0")|int %}

- Home the printer using

G28 - Set hotend to extrusion temperature

M104 S{EXTRUDER_TEMP} - Load the first filament to be used with

T{initial_tool} - Move to park position with

AFC_PARK - Lower the hotend to standby temperature with

M104 S{S_EXTRUDER_TEMP} - Perform any other necessary pre-flight tasks (e.g., heat soak, re-homing Z, bed meshing, prime/purge line, etc)